Premade Pouch Filling Sealing Machine

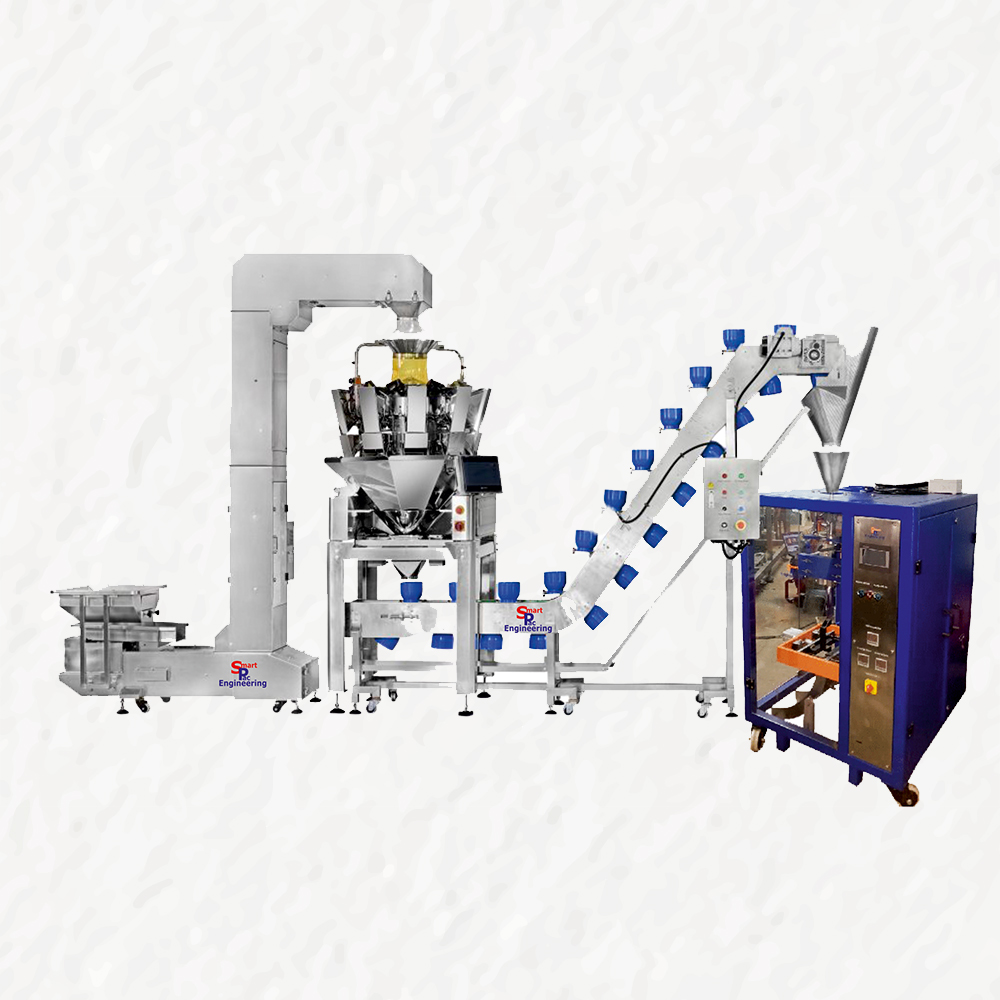

SPEG Automatic pouch filling and sealing packaging machines that automatically open, fill and seal pouches from flat to doy style, sachet packaging, stand up pouches or box style with side gussets. These pouch filling machines are designed for a fast changeover with minimal set up for various sized premade pouches so you can make different pack on the same machine. Built with Schneider PLC’s and Servos, SMC and Festo pneumatics, Omron temperature controllers and Schneider switches they also meet international standards pouch filling machines.

Our Premade Pouch Filling Machine can be used to fill liquids, pastes, granules and dry powdered products whether you are a small company or corporate. And they are ideal for the food, pharmaceutical, cosmetic, Non-food, confectionery, agriculture and chemical industries.

Please view our range here or contact our experts engineer to see how you can improve packaging efficiency in your business.

- SPEG-M-700

- SPEG-W-700

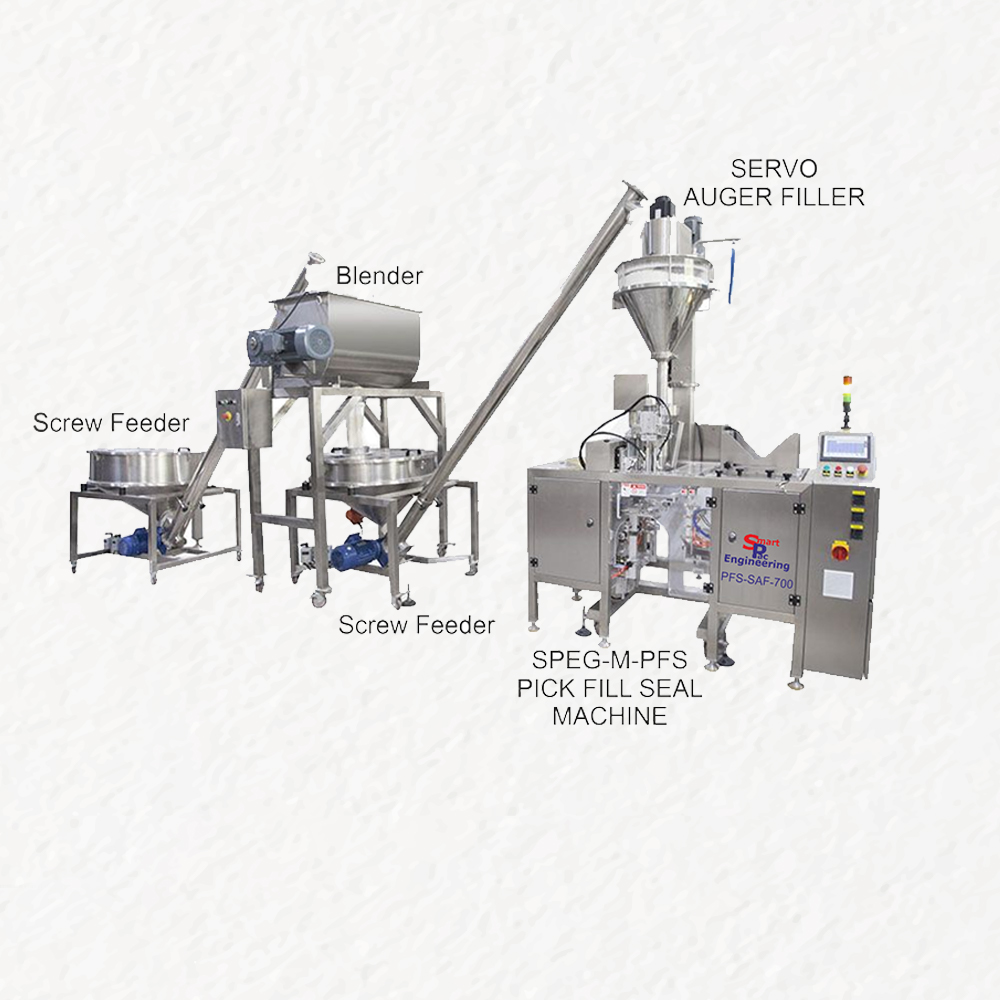

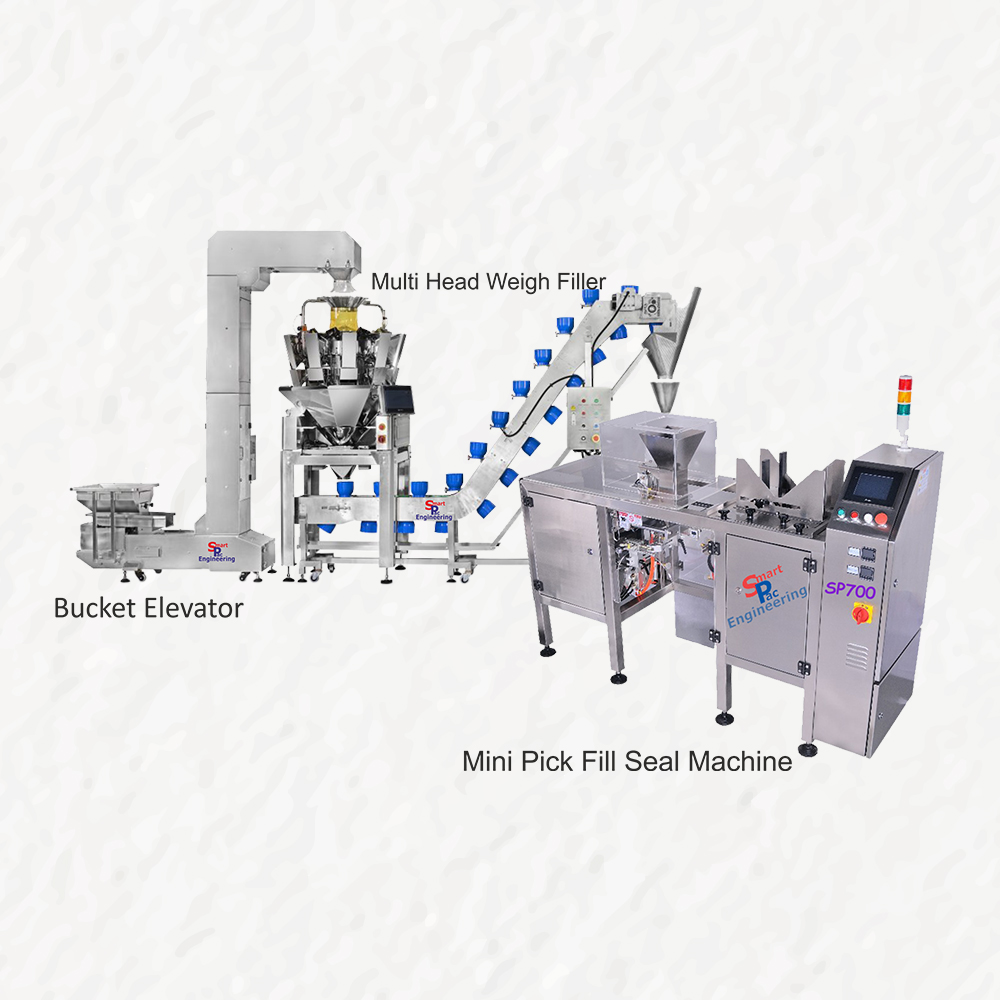

SPEG-M-700 MINI POUCH PICK FILL AND SEAL MACHINE. STANDARD AND GUSSETED POUCH

The SPEG-M-700 Mini Pick Fill series is built to local standards. This pouch filling machine, often requiring only one operator, comes with many automation features and the latest technology from around the world. As an entry or middle level pouch filling machine it can be adapted to suit all premade flexible packaging solutions.

Manufactured in India, the SPEG-M-700 Built locally to high Indian and international standards it utilises the latest in automation technology. Equipped with quality parts like Schneider, Delta, Omron, and SMC, Festo Pneumatic it includes an intelligent screen function for a quick Pouch size changeover. By packing all Pouch styles, flat pouch, premade doy, gusset premade pouch, you can produce many different Size on the one machine and increase productivity on your production line.

| Bag Styles | Premade Pillow pouch’s, Gusset Pouch’s, Flat Bottom, Doy Pouch with zipper |

|---|---|

| Bag Size | 75-280mm W, 130-380mm L |

| Speed | UP TO 20 PPM |

| Power Supply | 415V, 50Hz, 4.2kW |

Process

Pouch Loading

The process starts with up to 5 empty pouches being placed into the adjustable cartridge. Bags can be loaded while the machine is in operation. The machine is designed with a quick 5-minute Pouch size changeover, to provide efficiency on your line. These machines are simple to operate, use the latest in suction technology and are tested on all sizes and materials. .

Pouch Opening

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators. They are rotated to the fill area and opened. Multiple bag detection switches are used at various points in the cycle to ensure correct bag placement and full bag opening. Should a reject bag be detected it is ejected from the machine and the process continues. Rejected bags can be inspected by the operator and re-used if good.

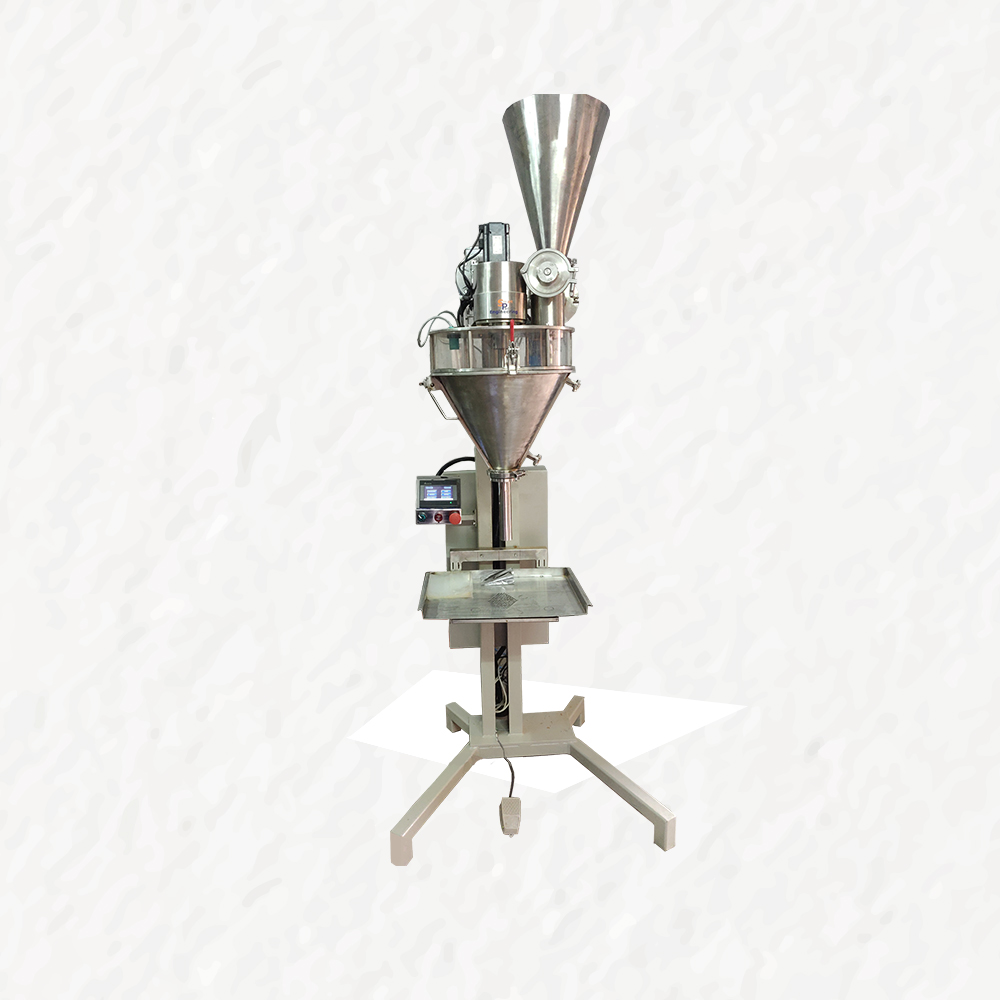

Pouch Filling

Product enters the transition chute while the bag is being opened below. Upon pouch detection the chute enters the pouch and opens its gates. Product is dispensed immediately. Without spillage and protection, the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler or manual, through the ‘’open gate’’ during filling. Pouches are held in place with our ‘’pouch -hold’’ gripper system. This allows for heavy weights and shock loads without disturbing pouch position. Once filled the pouch is pulled is tight position for sealing.

Features

- Food grade stainless steel construction

- Outfeed conveyor

- Anodised aluminium parts

- Schneider PLC & HMI

- Automatic program setup

- Quick Pouch size changeover

- Guarding and interlocks Systems

- Leading Brands; Omron, Schneider, SMC, Festo