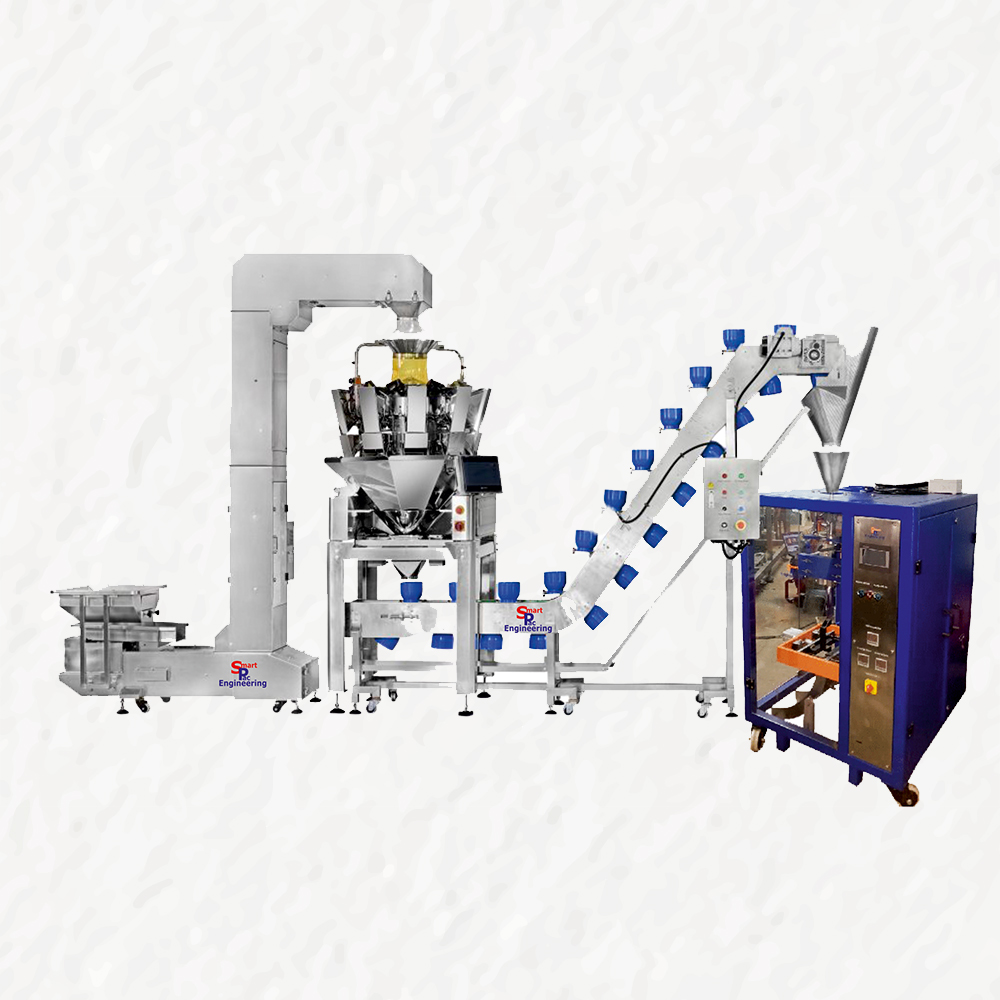

Premade Pouch Filling Sealing Machine

SPEG Automatic pouch filling and sealing packaging machines that automatically open, fill and seal pouches from flat to doy style, sachet packaging, stand up pouches or box style with side gussets. These pouch filling machines are designed for a fast changeover with minimal set up for various sized premade pouches so you can make different pack on the same machine. Built with Schneider PLC’s and Servos, SMC and Festo pneumatics, Omron temperature controllers and Schneider switches they also meet international standards pouch filling machines.

Our Premade Pouch Filling Machine can be used to fill liquids, pastes, granules and dry powdered products whether you are a small company or corporate. And they are ideal for the food, pharmaceutical, cosmetic, Non-food, confectionery, agriculture and chemical industries.

Please view our range here or contact our experts engineer to see how you can improve packaging efficiency in your business.

- SPEG-M-700

- SPEG-W-700

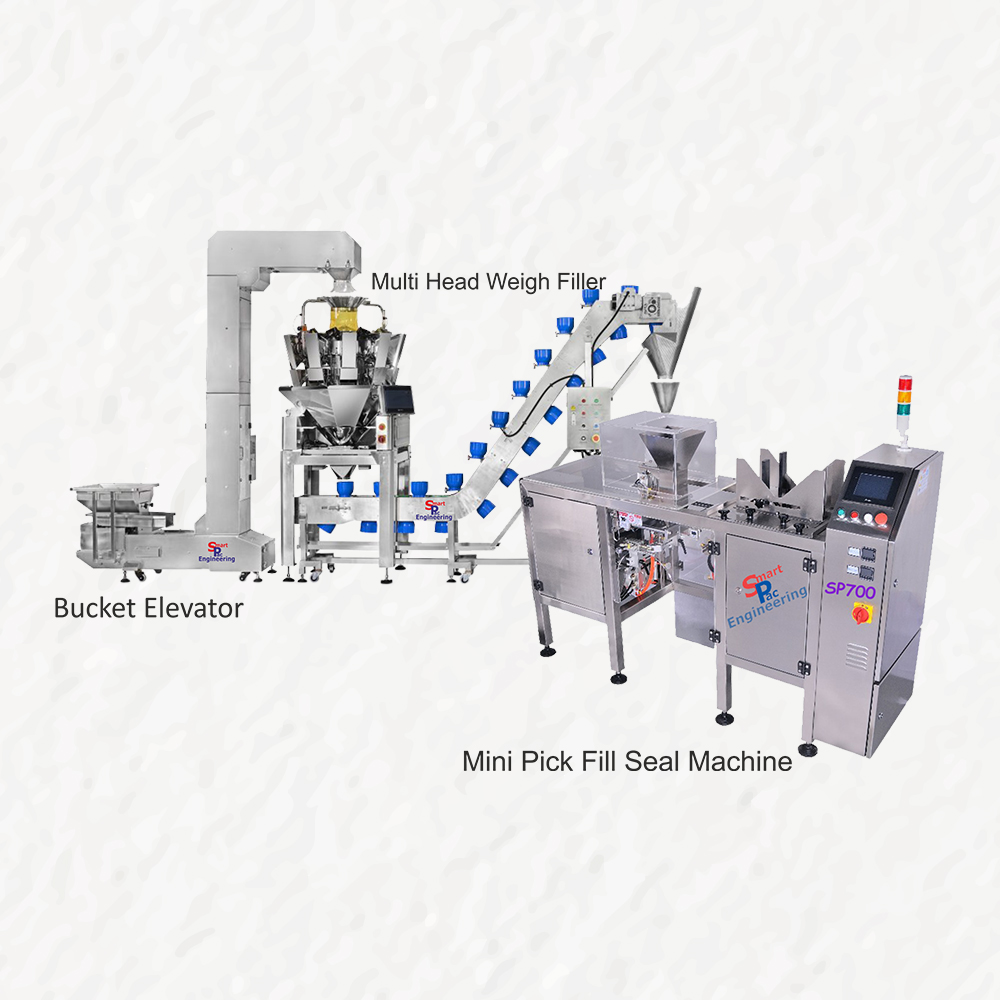

SPEG-W-700 WALKING BEAM POUCH PICK FILL SEAL MACHINE

The SPEG Pouch machines have the versatility to work with many different styles of pre-made pouches. Our quick adjustment system makes work much easier and allows you to save time. It enables you to change bag sizes in a matter of minutes and to reproduce this setting whenever needed. This is the perfect solution when you have multiple pouches to run Save Recipes on the touch screen.

Pouch Loading A pick and place system are used to transfer the pouches form the magazine to the walking beam grippers

Pouch Opening The walking beam is a reciprocating member with fingers mounted to transfer the pouches from one station to the next. The pouches’ mouth is opened by vacuum pads provided. The open mouth is ready for accepting the fill of product. Post filling the pouch’s mouth is closed and transferred to the sealing station. Cooling of the sealed area is the next operation. Discharge conveyor is provided to carry the finished pouches. Should a reject bag be detected it is ejected from the machine and the process continues. Rejected bags can be inspected by the operator and re-used if good.

Products

Products packed Powder, Granule, Dairy powder, Protein powder, Spices, Flour, Oats, Pasta, Pet foods, Cookies and moreFEATURES

- Stainless Steel Construction

- Schneider PLC

- Schneider HMI

- Omron sensors

- Schneider switches, push buttons, pilot lamps

- Omron temperature controller

- Festo and SMC pneumatics

- Pheonix terminals

- Full Safety Guarding

- CE Approved Electrical item

| Bag Styles | Premade Pillow pouch’s, Gusset Pouch’s, Flat Bottom, Doy Pouch with zipper |

|---|---|

| Bag Size | 75-220mm W, 130-290mm H |

| Speed | up to 50 PPM |

| Power Supply | 415V 50Hz |