Secondary bundle pack automation

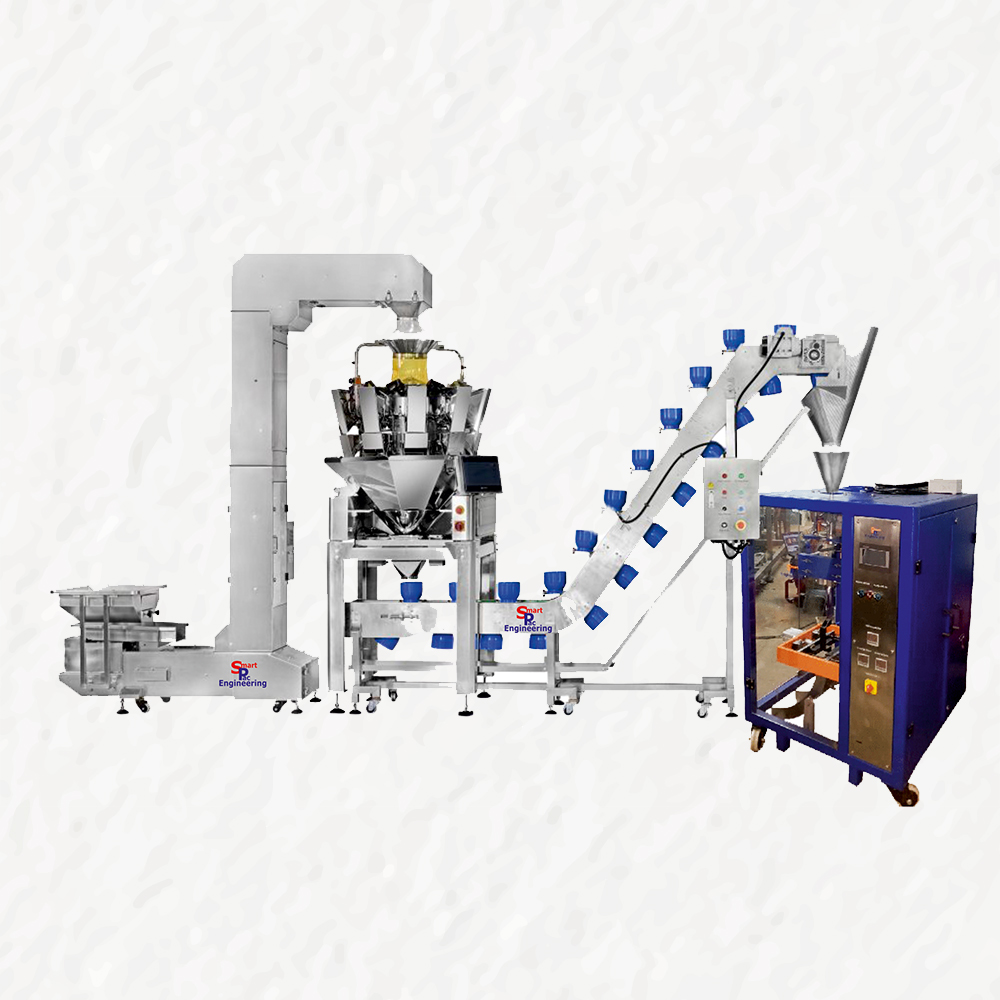

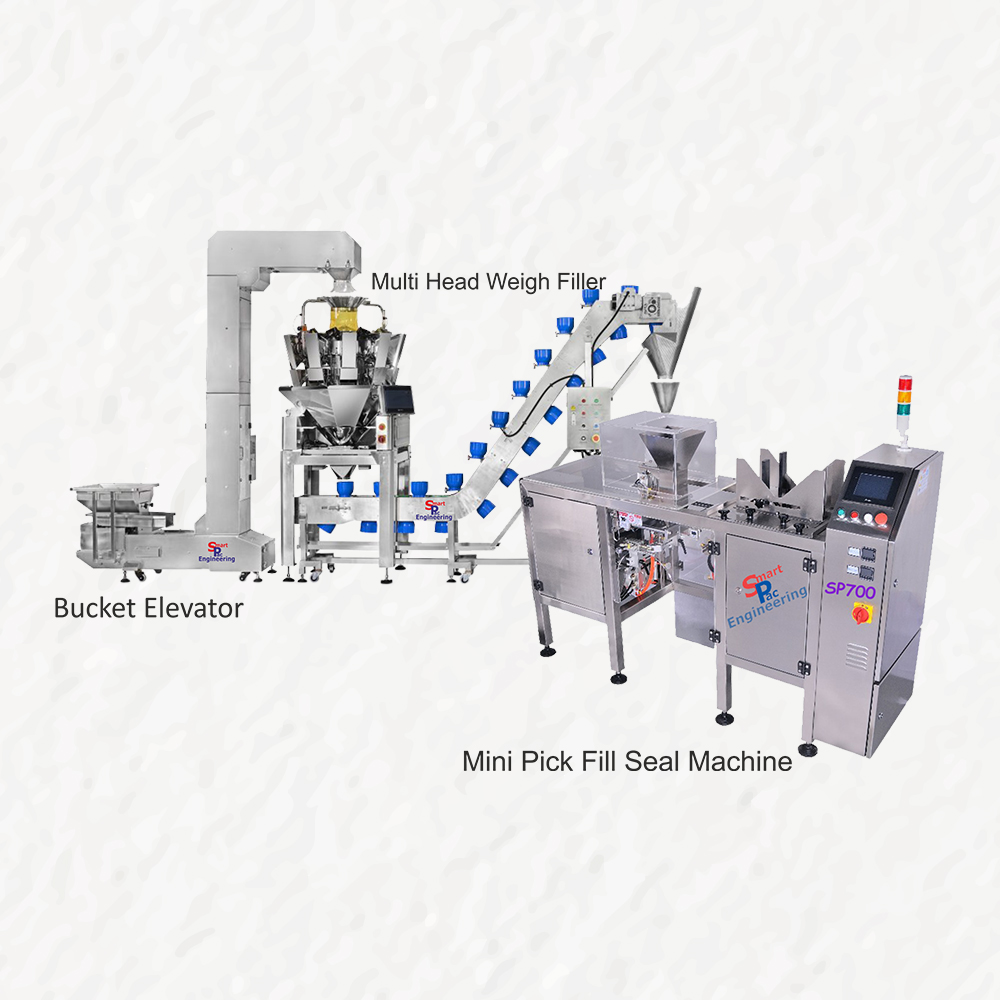

Secondary Packing: The best suited option for packing the product in a pattern that does not damage or deface the product and makes it user friendly for transporter to effectively deliver the goods at the doors of the customer. This system is very helpful in counting and avoiding any kind of pilferage thereby avoiding any negligence from the shop floor.

We provide excellent solution for this, and we create the mechanism for counting and collating the bags as per the customer’s requirement and then pack the same to a secondary bundle as desired by the customer.

We herein offer the best suited conveyor system and accessories for the secondary packing providing the best solution to combat Idle Labour, Pilferage and easy handling.

AIn this process the packed pack with the bundling or as you desire moves towards secondary packing and sealing mechanism. At junction on the conveyor 5,6,7 or as many packs as you desire can be planned to be collaged to move towards the process bundle packing mechanism. The bundles thus packed can be put into your cartons for supplied to the market as you desire.

Secondary bundle pack automation is an important aspect of the food industry. It involves automating the process of packaging products in secondary containers such as boxes or crates. More than anything, this type of automation can improve efficiency, reduce labour cost, and increase product consistency and quality.

Here are some steps that can be taken to automate secondary bundle pack operations in the food industry

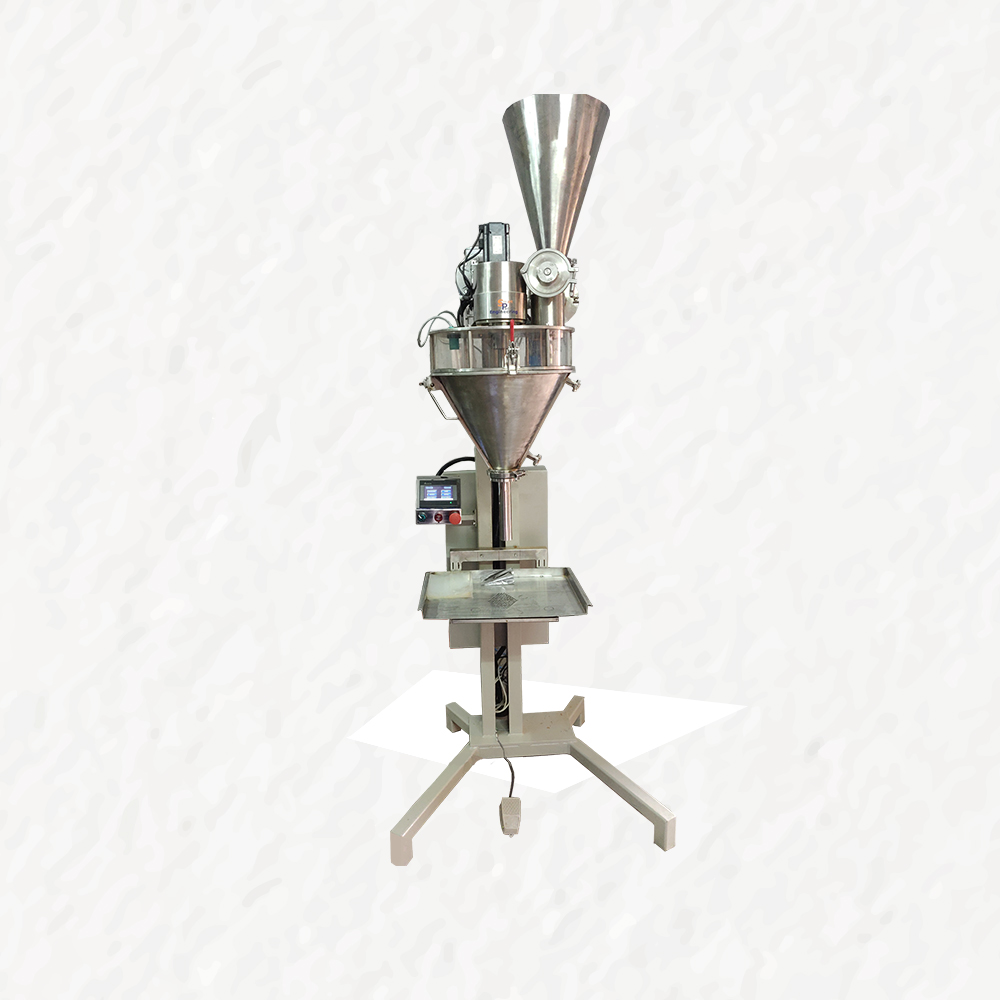

Features

- Stainless Steel Top & Side Covers

- Quick Release Clamps

- Stainless Steel Spilt Hopper

- Slow or High-Speed Agitator (we are using VFD)

- Stainless Steel Contact Parts 316