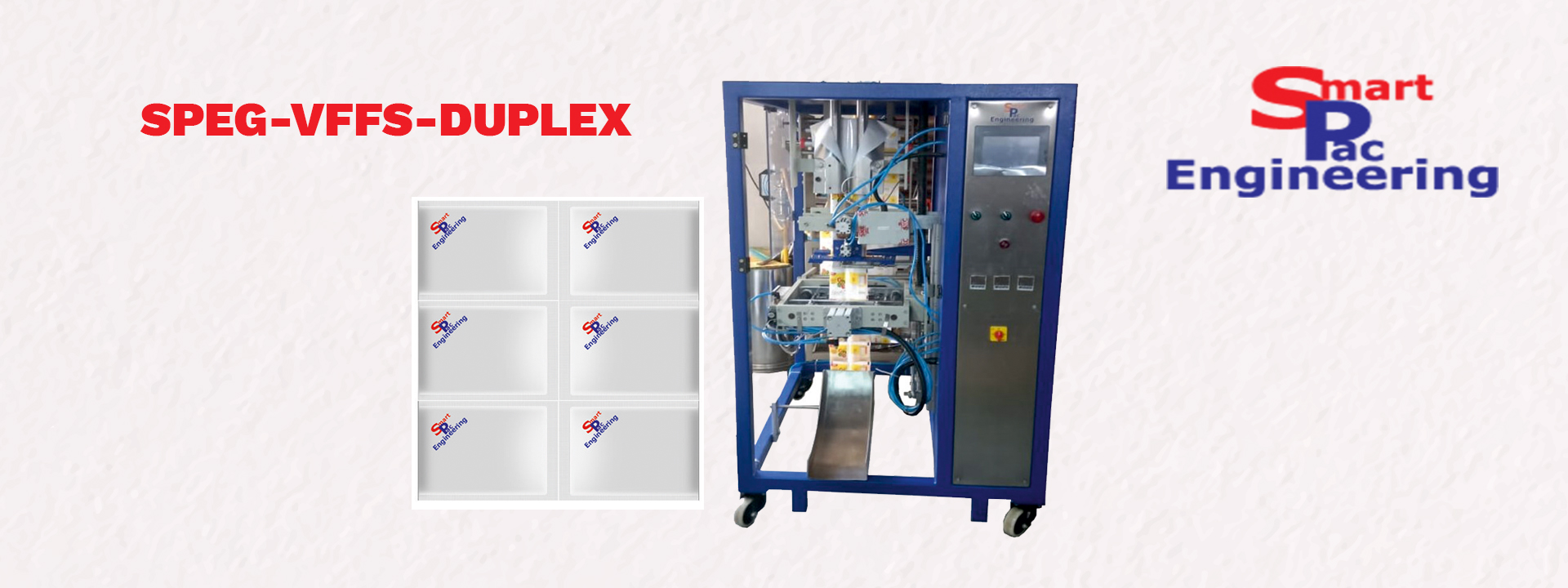

Duplex Machine

Three side seal Duplex Machine:

This is a platform where we use a specially designed collar by which we can have 2 Nos. of 3 side seal packs side by side. The other advantage here is you can even pack 2 different or same products simultaneously without sacrificing the speed.

A duplex packing machine is a type of packaging equipment that is designed to automatically fill and seal two identical packages simultaneously. The machine is typically used in the food and beverage industry, as well as in the pharmaceutical, Bio-Fertilizer and cosmetic industries.

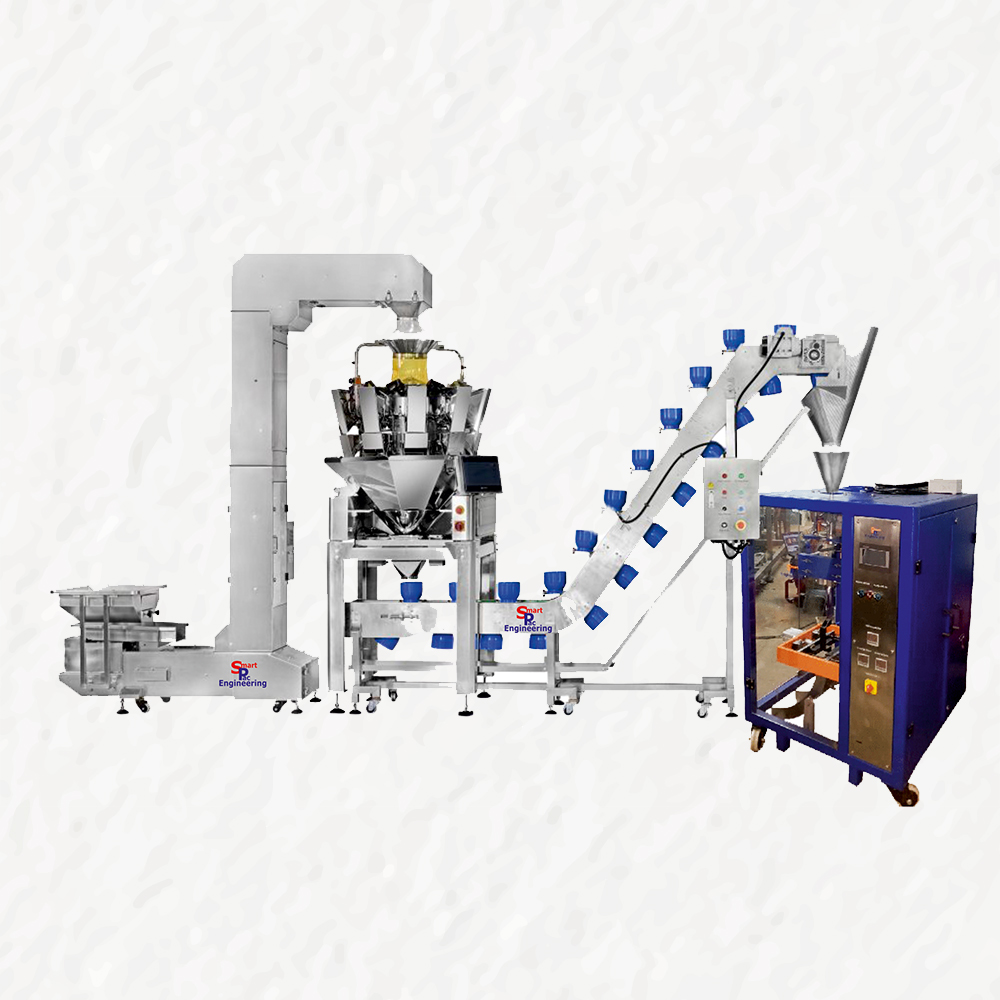

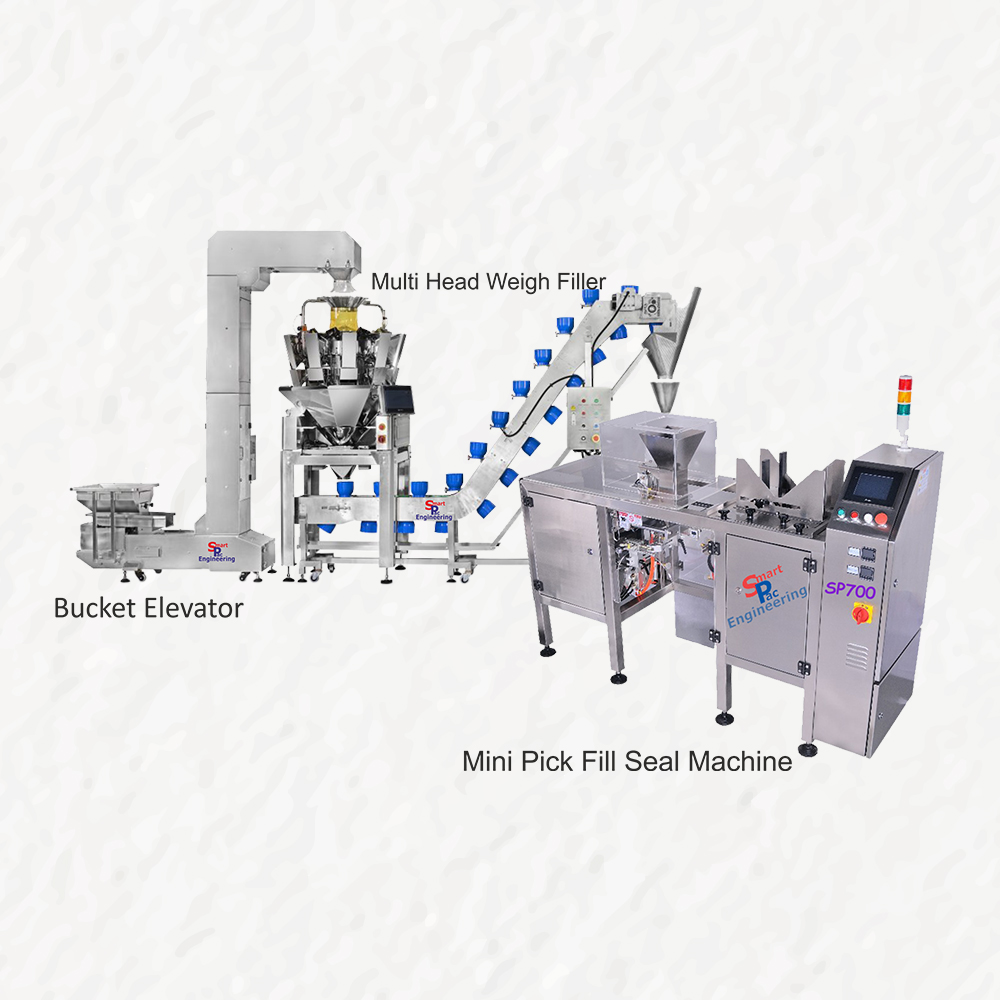

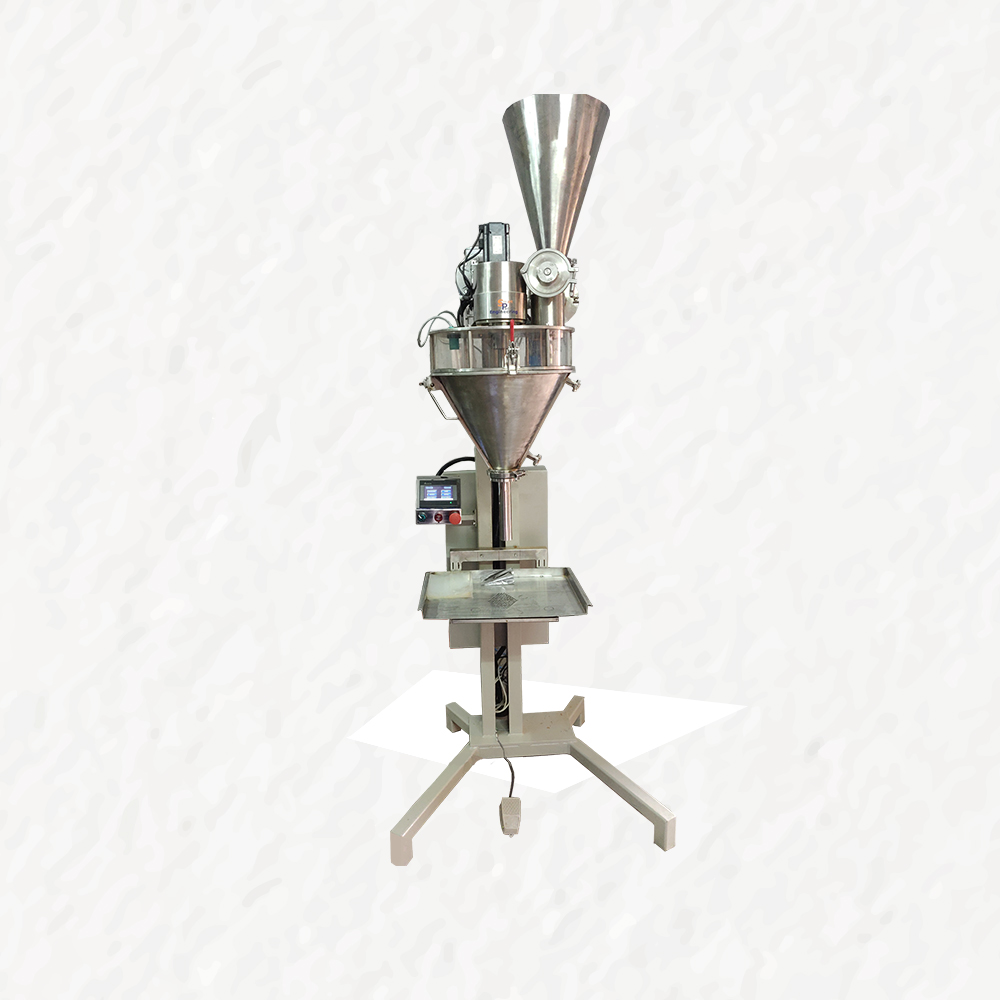

Duplex packing machines are designed and built in various configurations and can be used to package different types of products such as granules, powders, liquids, pastes and solids. The machine can be equipped with different types of filling systems such as volumetric or weigh filling systems, depending on the product that needs to be packaged.

The machine works by feeding two rolls of packaging material into the machine, where they are formed into bags or pouches. The product is then automatically filled into each pouch simultaneously, and the machine seals and cuts the pouches before they are discharged from the machine.

The duplex packing machine can operate at high speeds, enabling it to increase the production capacity of a manufacturing facility. The machine works by feeding two separate product streams into two different feeding systems, which then dispense the products into their respective packaging units.

Duplex packing machines are designed to increase the production efficiency and speed of the packaging process, while reducing the need for manual labour. They are also designed to be easy to operate and maintain, with features such as touch-screen controls.

The process of filling and sealing the bags involves several steps, including:

Forming the bags: The packaging material is fed into the machine, where it is formed into the shape of a bag or pouch.

Filling the bags: The product to be packaged is dispensed into the bags through the filling stations. The filling system may be designed to dispense a fixed amount of product, or it may be adjustable to accommodate different quantities.

Sealing the bags: Once the bags are filled, they are sealed using a heat-sealing mechanism. The sealing system may use different types of sealing technology, such as ultrasonic sealing, hot air sealing, or heat sealing.

Cutting the bags: Once the bags are sealed, they are cut to the desired length and separated from each other.

Duplex packing machines can be customized to meet specific packaging requirements, such as different sizes, shapes, and materials. They can also be integrated into larger packaging systems to further increase production efficiency.

Duplex packs reduced the consumption of packing material by almost 8%. Using these packs one will be able to transfer the expensive content through the fold without any product getting stuck in the crevice’s.

Overall, duplex packing machines are an efficient and cost-effective solution for packaging two products in a single package, making them a popular choice for many manufacturers in the food and beverage industry.

Features

| Machine | SPD400 Duplex | SPEG-300-I | SPEG-400-I |

|---|---|---|---|

| Nominal Speed | Up to 80ppm | ||

| Connect Load | 6kw,415V 3Ph, 50Hz | ||

| Machine Construction | MS/SS & Contact Parts are in SS316 | ||

| Pouch Width Size (mm) | 75 - 200mm | ||

| Pouch Height Size (mm) | 50 - 170mm | ||

| Fill Volume | Up to 200g | ||

| Packaging Material | All heat sealable Laminates | ||

| Film Pulling | Draw Down Bar / Servo | ||

| Horizontal & Vertical Seal | Pneumatic / Servo | ||

| Air Consumption | 6Bar |